The cooling of gas flows by injecting water or other coolants is a very common application for our spray nozzles. Correct nozzle selection is of critical importance in many spray cooling applications as the properties of the spray will determine how quickly heat is absorbed and where the spray will reach within a given gas flow.

Material of Gas Scrubbing Nozzle

Air Inlet Cooling

Cooling Deluge

Process Gas Cooling

Pond Cooling

Cooling Tower

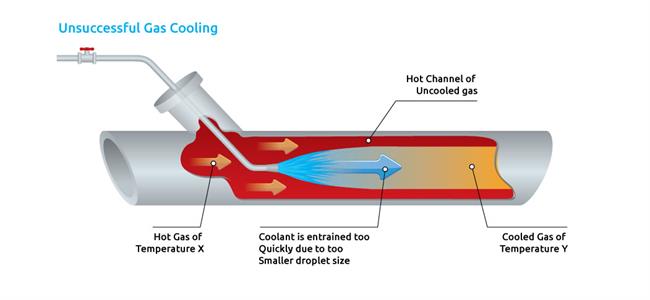

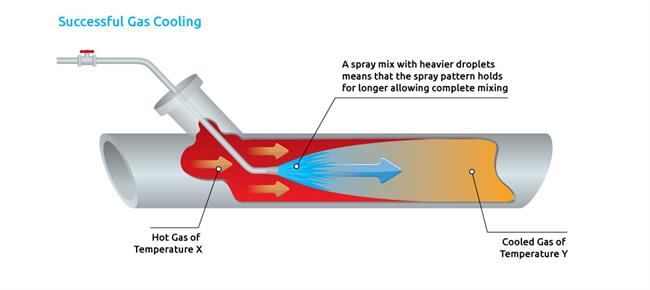

When spraying into a hot gas flow above the boiling point of the coolant most of the cooling is caused by taking heat from the gas to evaporate the fluid. The rate of evaporation will depend on the average droplet size of the spray. Sprays consisting of smaller droplets will evaporate far more rapidly than sprays containing larger droplets. In fast moving gas flows this can be very important as often cooling needs to be achieved before the gas reaches another point in the process. Correct nozzle selection can thus reduce the need for long quench chambers.

To learn more about which spray nozzle would be right for your gas cooling application, please explore the specific categories listed below, or contact our experienced engineers.

Many facilities or processes in hot, dry areas can benefit from using spray nozzles to cool the inlet air streams.

Evaporating water into the inlet air can provide critical cooling of heat sensitive areas such as electronic server rooms or animal enclosures.

It can also provide significant increases in the efficiency of equipment such as gas turbines or air-cooled condensers by cooling the air and increasing the relative humidity level of the inlet air streams to these units.

Spray nozzles can provide an effective and economical alternative to the use of electric chillers in many applications.

Important factors to consider:

CYspray provides a range of high-quality nozzles that are useful for reducing the temperature of various components and parts using a deluge spray.

Many production processes require the product to be hot during work and then cooled back to ambient temperature.

In metal processing industries, castings, extrusions, and hot-worked products fall into this category, as do any components that have been heated treated. In the food industry, many products are packaged hot and must be cooled before storage and shipment.

Regardless of whether you are cooling steel or soup.

Important factors to consider:

Nozzles are used for quenching in commercial and industrial applications around the world.

In many processes gas is raised to temperatures that could easily damage downstream equipment.

This can either be by direct combustion, as in the case of flue gas or by secondary heating.

The quickest and most effective way to cool a hot gas is through the evaporation of an injected liquid.

Changing the phase of the injected liquid to gas consumes enormous amounts of energy compared to sensible/direct contact cooling.

In evaporative gas cooling, a mist of water is sprayed into the hot gas.

In many cases, this is flue gas from a combustion process. The water then evaporates, cooling the system rapidly as the energy is used to change the water from liquid to gas.

When a volume of water is atomized into smaller droplets, more surface area is exposed, allowing the evaporation rate to increase.

The rate of evaporation is often criticized as the gas must reach its final temperature before a fixed point downstream.

The evaporation rate is dependent on the droplet size, temperature differential, and partial pressure among other variables.

Important factors to consider:

Cooling ponds are used to lower water temperature through contact cooling with the surrounding air.

Static ponds often have low cooling efficiency and require a lot of space as only the surface of the pond is in direct contact with the air, resulting in relatively expensive use of valuable land.

CYSpray offers a wide variety of spray nozzles which can dramatically lower the expense and footprint of cooling ponds.

By spraying and atomizing the water from the cooling ponds into the air, spray nozzles significantly increase the surface area of water exposed to the air, thus improving the cooling efficiency and decreasing the area needed for the pond.

In some cases, the use of spray nozzles can reduce the land required to 5% of the area needed for a static pond.

Important factors to consider:

Cooling & lubricating mill rolls used for the production of steel and aluminum

Important factors to consider:

We help you avoid the pitfalls to deliver the quality and value your spray nozzle need, on-time and on budget.

We will contact you within 1 working day, please pay attention to the email with the suffix “info@cycospray.com”.