Humidification is a process of controlling the humidity of the air, it’s necessary for some application to adjust the humidity like the warehouse, electronics factory, greenhouse and any other application where humidity is critical to the process.

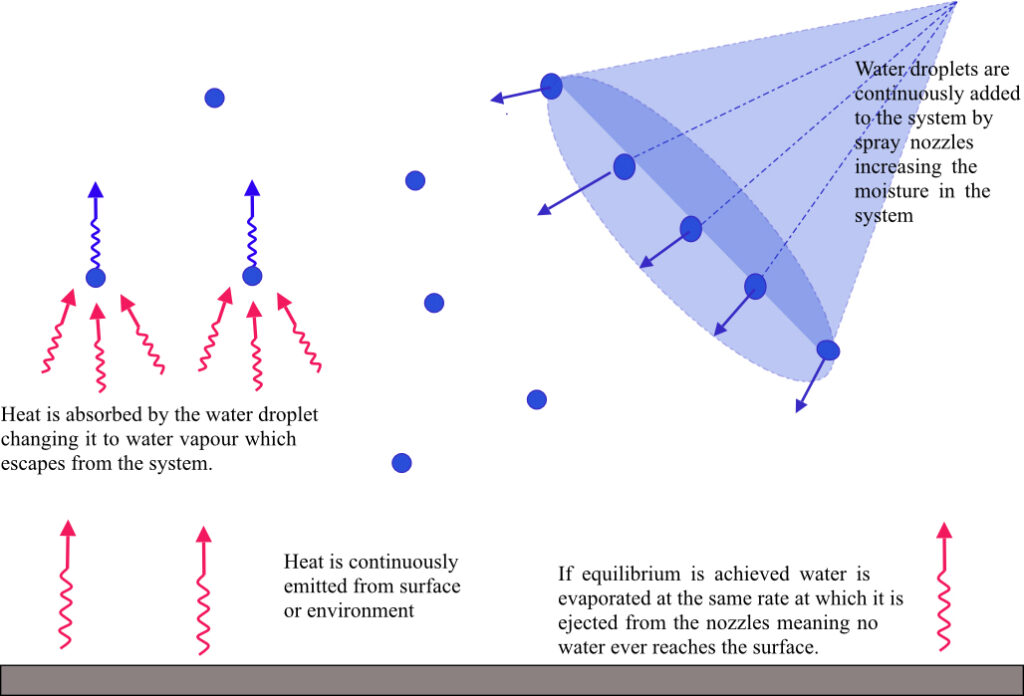

Increasing the humidity levels can be important in a variety of environments. The key to successful humidifying sprays is the controlled spraying of finely atomised sprays. If too much liquid is put into the system then condensation or precipitation may occur. If too little is put in then the desired levels of humidity will not be maintained.

Warehouse

Electronics factory

Moisten air in ducts

Greenhouses

More humidification application

Humidifying systems generally only require very moderate levels of spray. The amount of water needed to raise the humidity of a given environment will depend upon:

1- The ambient humidity level i.e. the starting point.

2- The rate at which the air in the area is exchanged with the wider atmosphere. This will depend upon ventilation and air movements.

3- The temperature of the room. This will affect evaporation rates as well as the overall carrying capacity of the air.

In order achieve swift humidification from a spray nozzle one needs to keep the droplet size as small as possible and to distribute the water over a wide area. This will help the small droplets evaporate into the air as quickly as possible raising the humidity level.

We help you avoid the pitfalls to deliver the quality and value your spray nozzle need, on-time and on budget.

We will contact you within 1 working day, please pay attention to the email with the suffix “info@cycospray.com”.