Dust is a common by-product of many industrial processes. How serious a problem dust is depends upon the process and the nature of the dust. At one end of the scale production of dust can be merely an unpleasant inconvenience – at the other end of the scale it can pose a severe risk to humans and equipment. At the more severe end of the scale the reduction of dust contamination is often mandated by regulatory legislation, so effective dust control is a business-critical application.

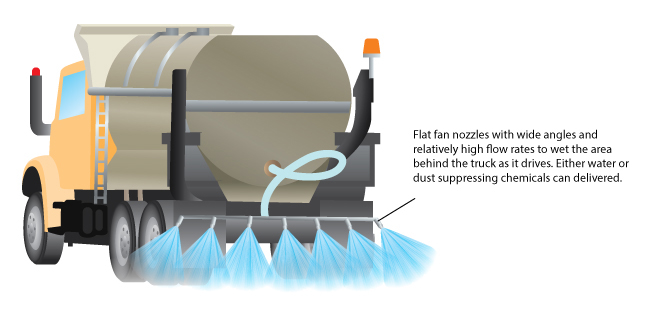

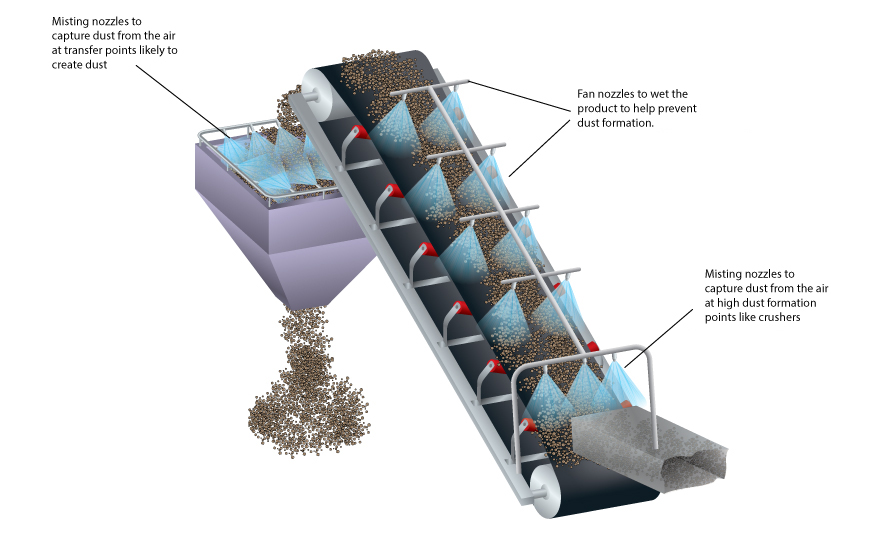

First, in a relatively confined space, such as air handling ducts and vents. Second, in an open area and relatively stationary state, such as crushers, dump pits, and other material handling locations. Third, in a semi-open area and in motion, such as the movement of conveying crushed stone, coal.

How about your dust circumstance? explore more below or direct inquiry our expert.

An overview of the main nozzles used in dust suppression applications can be seen in the diagram below and in the dust suppression nozzle selection table which can be accessed by clicking on the orange icon to the right hand side of this page.

In dust suppression applications a fluid is sprayed to either ‘capture’ dust from the air or to prevent dust from forming by wetting a surface. The engineering considerations (accessed by the blue menu to right hand side of this page) found in this section of our website aim to arm our customers with enough information to make an informed product selection. Details on the different nozzles suitable for dust suppression and how their design features relate to the engineering considerations can be found in the grey menu to the right hand side of this page.

Airborne dust can be captured using a water spray. Water sprays have an inherent maintenance advantage over filter systems as they typically do not have to replaced frequently to maintain effective performance, low-pressure drops, and overall system performance.

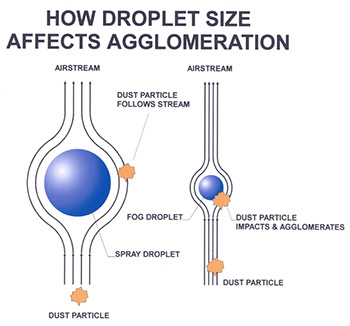

The premise is that when a water droplet comes into contact with a dust particle, they will agglomerate and the resulting combination will be too heavy to remain suspended in the air stream.

The water droplet/dust particle combination will then fall out of the air stream where the dust can be disposed of.

To obtain the most effective dust removal, the droplets should typically be 1 to 5 times the size of the dust that is being controlled.

If the drops are too small, they will be unable to agglomerate with and knock down the dust particles. Conversely, water drops which are significantly larger than the dust particles from an air barrier around themselves, preventing the dust from gaining direct contact and encapsulation/agglomeration with the water droplet.

Nozzles can spray a fog of correctly-sized water droplets to remove the dust from the air.

We can provide droplet size distributions to aid in the selection of the correct nozzle and operating parameters.

We help you avoid the pitfalls to deliver the quality and value your spray nozzle need, on-time and on budget.

We will contact you within 1 working day, please pay attention to the email with the suffix “info@cycospray.com”.