Sandblasting has a wide variety of uses. It can be used to strip pavement and as a paint removal technique. Sandblasting will polish and refine surfaces while removing dirt and contaminants. This polishing will create a great looking finished product or properly prime a surface for painting. Sandblasting can be used on strong surfaces like pavement or more delicate surfaces like table tops, and can even be used on precision parts such as small gears.

Rust Removal

Rust is a serious problem with metal products. In fact, it is the leading cause of property damage, as it corrodes metal and can spread quickly to other metallic surfaces. If not properly treated, rust can cause permanent damage. This damage is especially harmful to machinery, which could malfunction or be rendered useless if one piece rusts. Sandblasting is an effective tool in rust removal, which is essential to maintaining the integrity of metal products.

Safety

Sandblasting is a process that is both environmentally friendly and non-toxic. Because the process utilizes actual sand, there is no harmful dust to be breathed in. It does not make use of any material that is dangerous to people or the environment. The material used in sandblasting can be touched or inhaled without harm to an individual, and can be disposed of without any harm to the environment.

Excellent Results

Sandblasting is an extremely effective process. It can clean almost any surface, removing all contaminants that could damage the product or its appearance. Using sandblasting to clean a product will improve its functionality and longevity. When used for rust removal, it can actually repair damage that rust has done to the surface. Sandblasting is a very effective process to create a perfectly polished product.

Quick Details:

| Warranty: | 6 months |

| Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Farms, Restaurant, Home Use, Printing Shops, Construction works , Advertising Company |

| After Warranty Service: | Video technical support, Online support |

| Local Service Location: | None |

| Showroom Location: | None |

| Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided |

| Marketing Type: | New Product 2020 |

| Place of Origin: | China |

| Brand Name: | CY, CY spray |

| Condition: | New |

| Material: | Boron carbide |

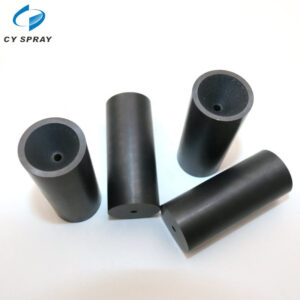

| Type: | Venturi nozzle |

| Application: | Sand blasting and cleaning |

| Product name: | wet sand blasting nozzles |

| Thread: | Fine |

| Model: | Water blast nozzle |

| Usage: | Wet blast |

| Jacket: | Aluminum jacket |

| MOQ: | 20pcs |

Packaging & Delivery:

Packaging Details:

Transparent Plastic Box+Carton+ Wrapping film

Special requirements are available (Wooden box or Pallet)

Port:shenzheng

Lead Time:

| Quantity(Parcels) | 1 – 1000 | 1001 – 3000 | >3000 |

| Est. Time(days) | 6 | 9 | To be negotiated |

Product Description:

Sandblasting nozzles used for clean machine. Water injection sand blasting nozzle with high performace to clean steel, stone and concrete surface. Wet blasting performace up to 20% higher than dry blasting.

Expected life with expendable abrasives .

Durable metal jacket

50mm corase thread or find thread

| Model | Water blast nozzle |

| Name | Boron Carbide Wet Blast Nozzles |

| Material | Boron carbide |

| Thread | Fine thread |

| Shape | Venturi |

| Size | Φ6,Φ8,Φ10,Φ12*175mm |

| Jacket | Aluminum |

CY spraying & purification tech.CO.,LTD was founded in 1997 and located in Chang an town, Dong guan city, Guang dong province, China. Specializing in the production of spray nozzles, plastic nozzles, mist nozzles, water treatment nozzles, sand blasting nozzles and other metal or plastic products. We has been formed R&D, production and sales of high tech company network integration.

CY spraying & purification tech.CO.,LTD has Japanese automatic CNC lathes(precision<=2um) and measurement systems for the nozzle follow,angle,impact, force,water distribution ,particle size ,etc. Detection accuracy are reached international level that we can supply a god quality products to our customers.

Our products of high quality widely used in a variety of coating, electroplating, electronic, steel, environmental protection and dust removal, purification, paper making, textile industry, food, vehicles, engineering machinery, petrochemical industry, paper making, ship making , humidifying, disinfection, cleaning, sand blasting, water treatment etc.

We help you avoid the pitfalls to deliver the quality and value your spray nozzle need, on-time and on budget.

We will contact you within 1 working day, please pay attention to the email with the suffix “info@cycospray.com”.